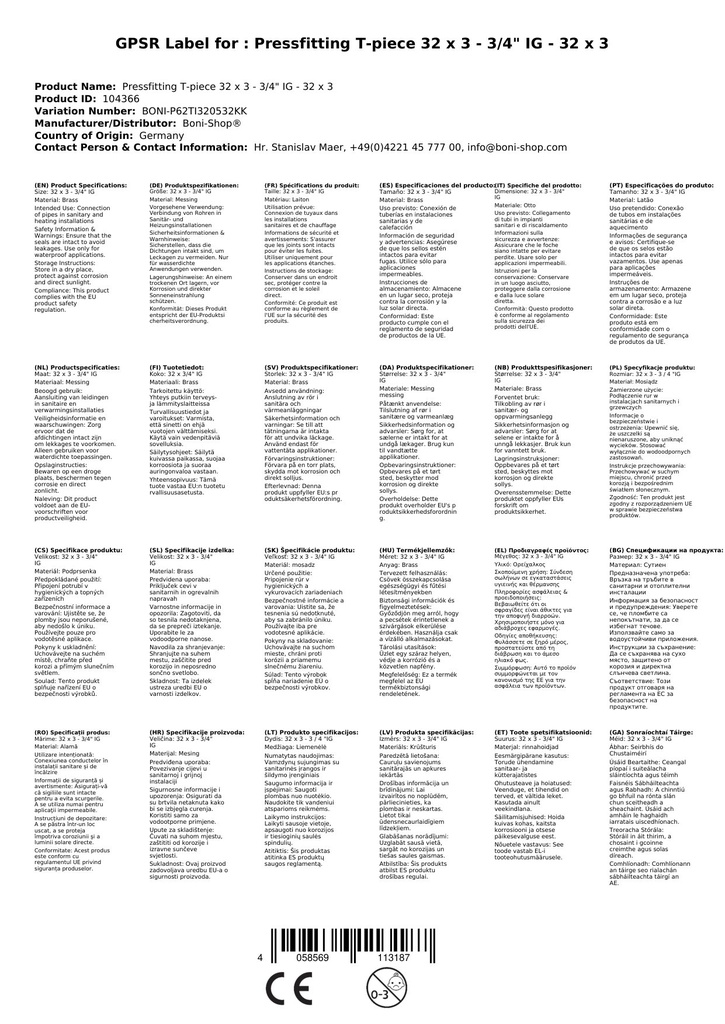

Pressfitting T-Piece 32 x 3 - 3/4" IG - 32 x 3A

Made in Germany

- Suitable for drinking water without restrictions (DVGW DW-8501BS5049)

- Corresponds to the UBA positive list

- Durability: 10 bar / 70° C / 50 years

- Maximum operating temperature: 95° C

- leak-proof when unpressed

- New modern contour - flow-optimized - free passage - almost no flow noise

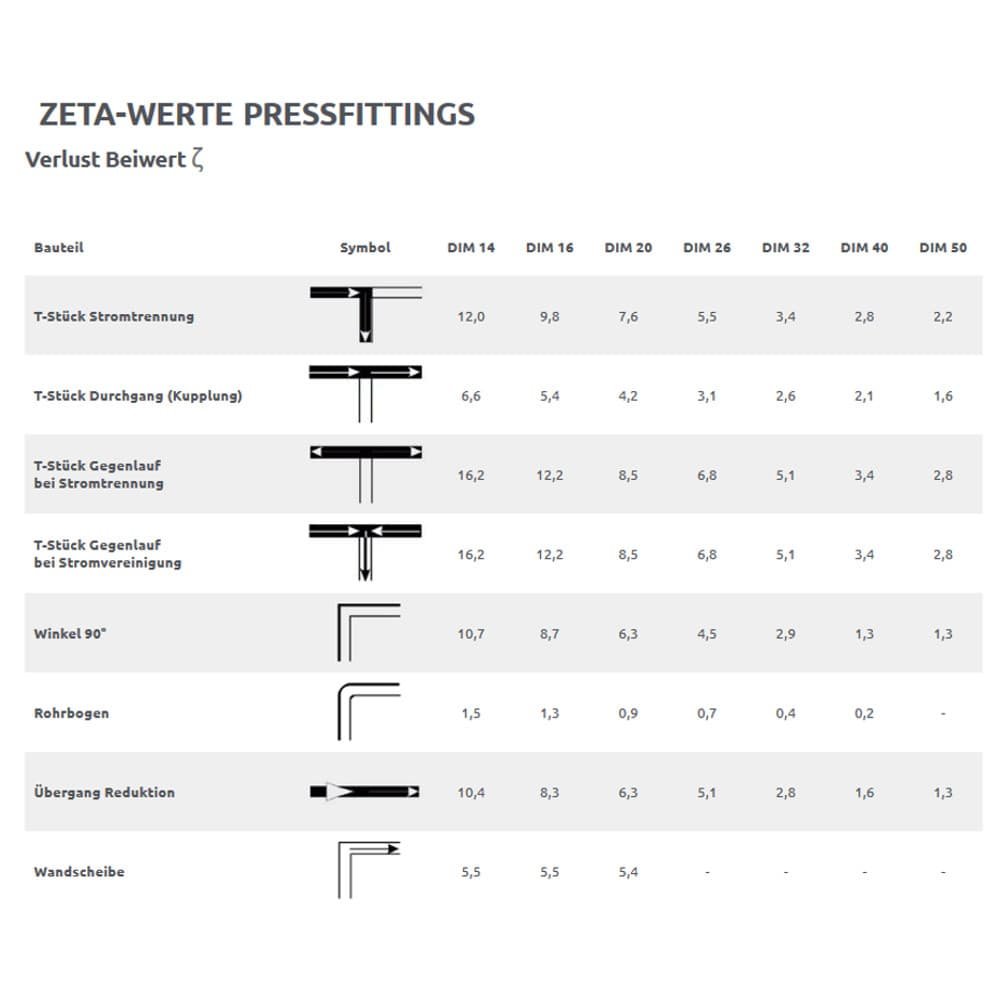

- best ZETA values: largest passage area = largest inner diameter

- low-lead or lead-free: all components are DVGW certified, correspond to the UBA positive list and meet the requirements of the drinking water ordinance

- one fitting system for two pipe systems: multi-layer composite and copper pipes, DVGW certified

- no pushing out of the pipe before the pressing process and through the guide ring; fits perfectly in the press jaw, gap-free connection = highest safety

- 2 O-rings due to the gap-free pressing = no ingress of oxygen

- Composite pipe system press fitting made of special brass (CU Zn 40 Pb2)

- Press sleeve made of stainless steel

- Plastic guide ring (black) for secure pressings even in forced positions

- Integrated inspection window inlet depth pipe in fitting in the stainless steel sleeve = added safety for the user

- Made in Germany

For a quick and secure pipe connection, you only need press fittings, our aluminum composite pipe, a pipe cutter, a calibrator and a suitable press tool with TH or U press contour.

For better understanding, we have provided a pictorial assembly instruction with the photos.

New! Multi-contour (TH + U)

Complete compatibility with TH and U press jaws up to the dimension 32 x 3.0 mm.

- 16 x 2.0 mm = TH + U compatible

- 20 x 2.0 mm = TH + U compatible

- 26 x 3.0 mm = TH + U compatible (25er press jaw)

- 32 x 3.0 mm = TH + U compatible

- 40 x 3.5 mm = TH

- 50 x 4.0 mm = TH

- 63 x 4.5 mm = TH

Assembly Instructions:

- Cut the pipe with a suitable tool

- After cutting, the pipe end must be calibrated and deburred with a calibrator

- Then insert the pipe into the fitting until it stops. The correct insertion depth can be recognized by the three inspection windows of the stainless steel press sleeve.

- Press it using a suitable pressing tool with a press jaw conforming to the fitting dimensions.

Please note that the use of composite pipes other than those distributed by Boni-Shop is at your own risk.

A regulation-compliant connection exists for all press systems only with system-approved components (fittings and pipes that have been tested together)

This applies to all composite pipe systems, independent of the manufacturer.