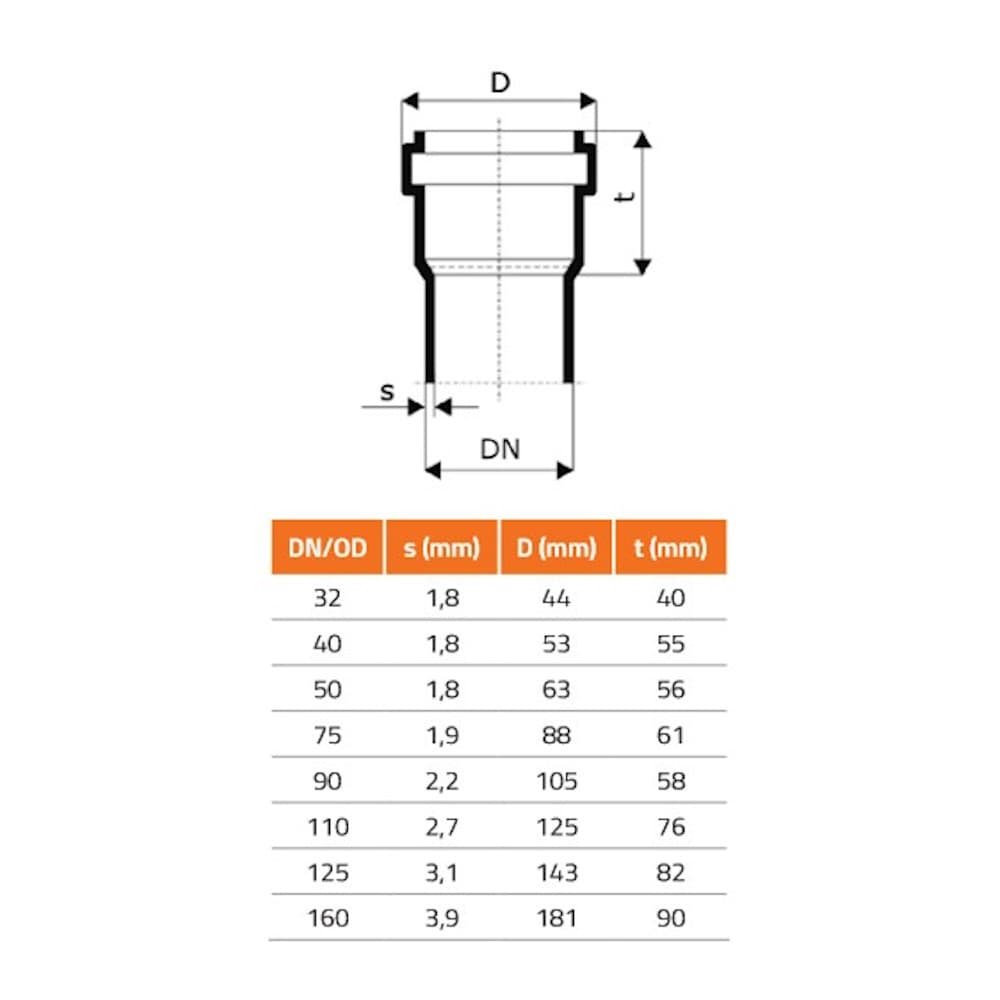

HTsafer DN/OD 160

This is how domestic drainage works today

Quick processing, secure sealing, optimal noise behavior,

- Perfect price/performance ratio

- Manufactured according to DIN EN 1451-1

- Made in Germany

- Extremely durable

- Simple and quick processing

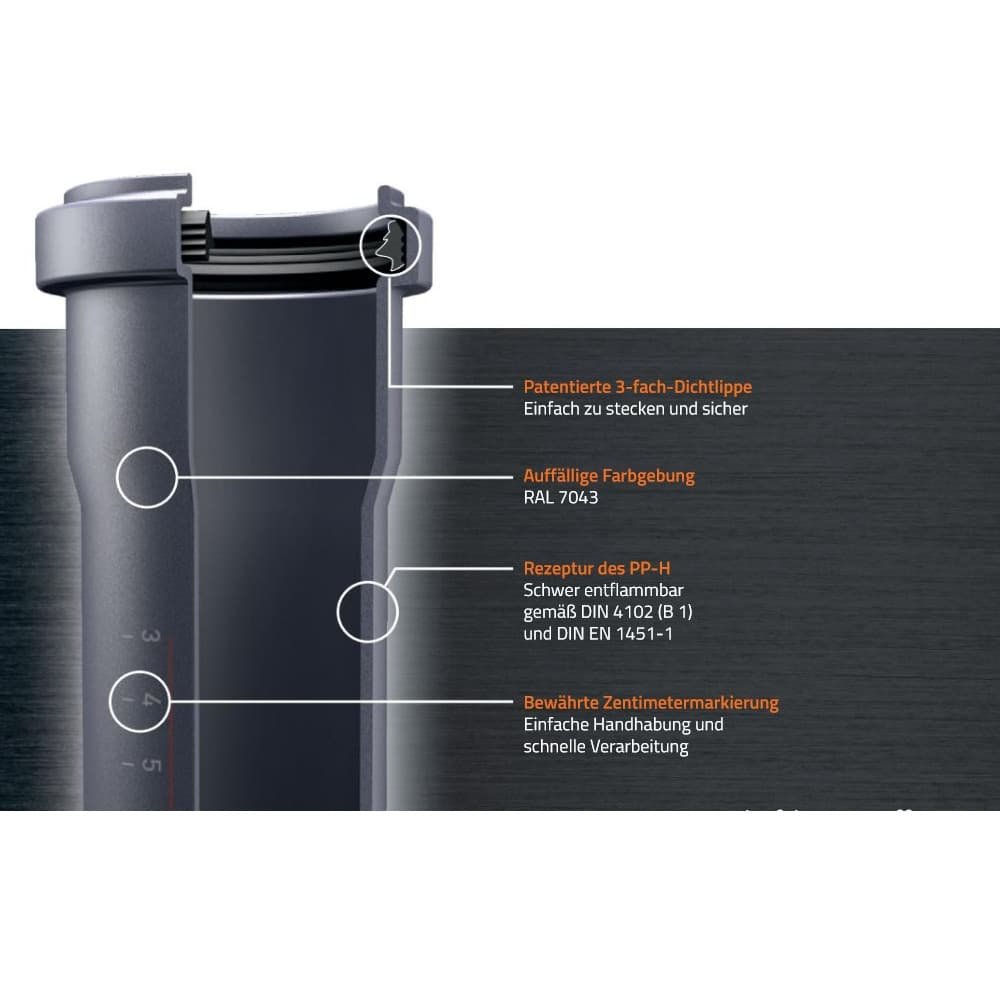

- Patented 3-fold sealing lip

- Exchangeable NBR seal

- Very good sound insulation

- Proven centimeter marking

- Flame-retardant B1

- Approved with the most common fire protection collars from various renowned manufacturers

- Approved with our pull-out protections up to a maximum pressure of 2.0 bar

- Also for central vacuum systems

Application:

Drainage within buildings as wastewater pipe, rainwater pipe, ventilation pipe

(see also areas of application: DIN 1986-4).

This pipe system can be very easily inserted, installed, assembled, and laid through plug connections with sockets into the chamfered end of the pipe (spigot end).

During assembly, the pipe is pulled out by one centimeter again after complete insertion to create an effective length compensation.

When laying the pipes and fittings, it must be ensured that the wastewater does not back up, or solid particles do not accumulate, which could clog the pipe system.

A minimum slope of 2 cm per meter is prescribed. HT branches and other fittings are therefore equipped with a maximum angle of 87 degrees (3-degree slope) to the main pipe.

The diameter of the HT drainage pipe system should be chosen neither too small nor too large. Too large diameters reduce the sufficient buoyancy of solids. Deposits and blockages could be the result. Too small pipe diameters carry the risk that the pipe will fill completely. The resulting air seal can suck out the odor trap. Odors from the downpipes could rise from the drain into living spaces.

HT pipes can be cut to any length with a metal or fine saw. A miter box can be used. Saw edges should be chamfered to achieve a proper connection between the HT pipe and subsequent parts. Burrs inside the pipe should also be removed to prevent damage to the seals and accumulation of deposits.

Material properties

Pipes and fittings made of polypropylene with the ability to withstand hot water, manufactured according to DIN EN 1451-1.

- Temperature application areas: -20° to 90°

- high chemical resistance; pH 2-pH 12 (acidic-alkaline) stable against biogenic sulfuric acid corrosion

- high abrasion resistance of polypropylene, resulting in longevity and operational safety

- excellent impact resistance and toughness

- low tendency to crack formation and crack propagation

- robust behavior under mechanical stress (e.g., high-pressure flushing)

- smooth surfaces, optimal hydraulics

- no incrustation, deposits cannot settle

- self-cleaning, resulting in long maintenance intervals